The Decision

Mid April, 2025 – Costa Rica

When I helped transferring the 24m sailing catamaran Costa Rica from Tahiti to Fiji earlier this year, my last three days, after having handed over the role as skipper to R., I had some time on the boat to plainly enjoy the atmosphere. While I was convinced that keeping Magayon II was not sustainable under the arrangement of cost sharing we had, it became increasingly clear to me that if we would sell Magayon II and I don’t have control over another boat, that would be it with sailing, except for the occasional charter or joining another boat for a few days. I remembered that P. had told me during the All Souls Regatta 2024 that he was planning to sell IRResistible, Sparkman & Stevens 36. That would be a more convenient boat for me age, with a cabin with standing height, shade in the cockpit and seaworthy enough to go a bigger tours in the Philippines. So while still on Costa Rice in Fijian waters I texted P. And asked him whether the boat is still for sale. It was.

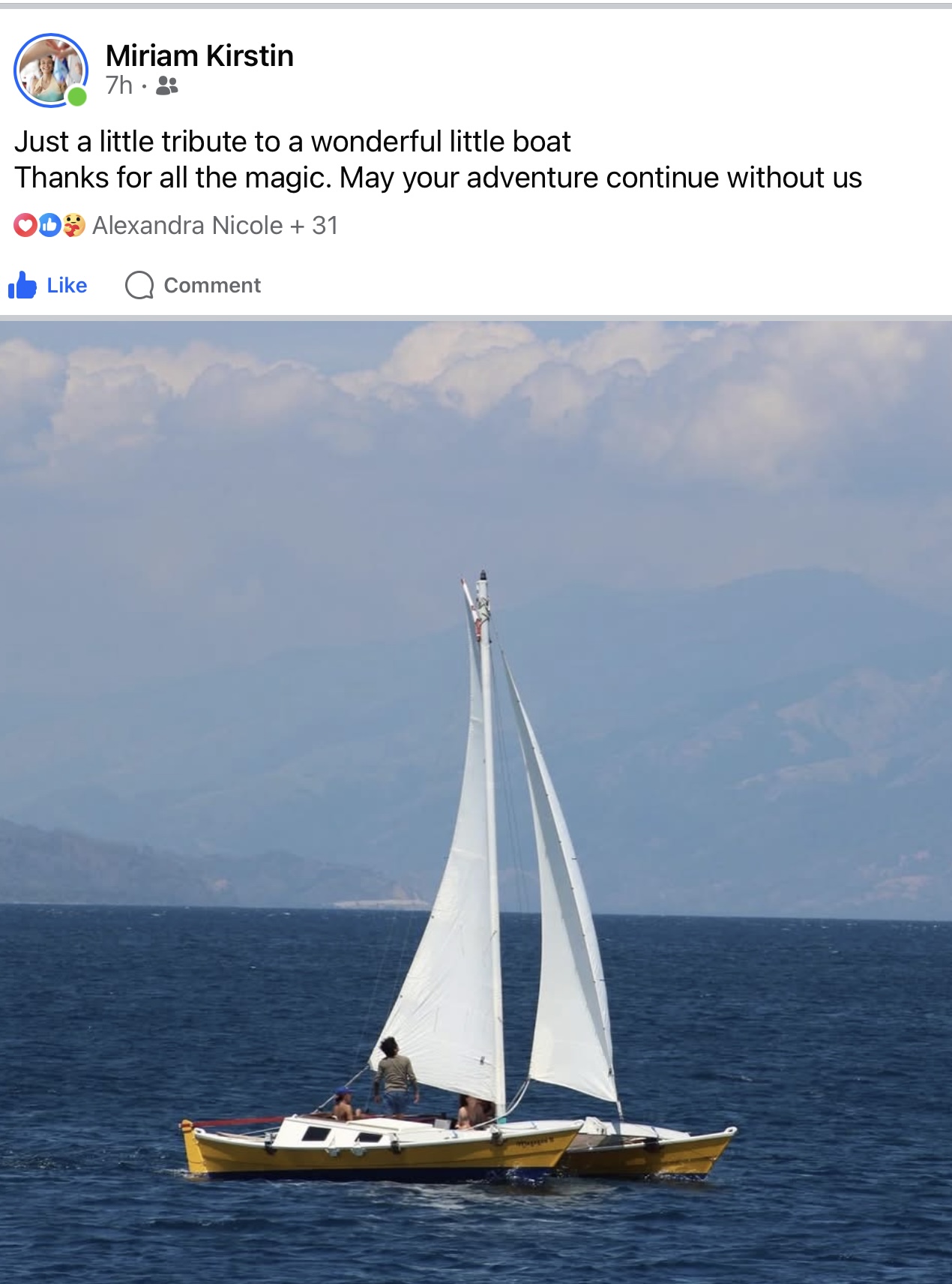

Sep. 11, 2025 – Handed over Magayon II to her new owners

After one of the boys who had shared the mooring cost of Magayon II had dropped out of the arrangement because he never had sailed her, and I sensed that the others were also not sure whether they would use her in the future, I advertised Magayon II with heavy heart, expecting that it would be difficult to find a buyer, considering that the people here are not into the maritime camping lifestyle that Magayon II is ideal for.

Luckily I was wrong. Two guys, from the US and Switzerland wanted to have a similar boat in Dumagete, where their families live. After many email inquiries and negotiations they came with their wives to Subic, we test sailed Magayon II the next day, and after that they agreed on the discussed price. I joined the first 10 nautical miles to introduce them to the boat when she took her on the voyage from Subic to Dumagete.

Very sad to let her go. But on the bright side we now had some starting capital for a potential purchase of IRResistible. I texted P. and we agreed on a date for test sailing her ein Puerto Galera.

Oct. 2-5, 2025 – Test sailing IRResistible in Puerto Galera

M. and I spent an extended weekend in Puerto Galera. The fist day we had a look at the boat and all the papers, the second day P took us out on a trip towards Verdi Island. There was not much wind, and several things went wrong, the throttle cable for example broke and we drifted for around an hour and 2 nm with the current towards Sabang until we had it fixed.

She is a 40 year old boat and the rig and sailing gear is reasonably OK. But it was clear that she needs a lot of work to make her suit the purpose for which we would buy her, coastal cruising in the Philippines. Examples: Electrical system, except for the cabin lights and the motor start circuits gone, anchor winch not working, fresh water pump not working, rainwater leaking inside at all travelers and the mast shoe, and no haul out for many years. Nothing I can’t fix. P. mentioned the price he would put her on the market for and said for friends it would be 20% cheaper. M. did not have any violent objections. So I said I would get back to him after doing some inquiries about maintenance and repair cost.

Purchase

A few sleepless nights, inquiries at boatyards re. haul out, consultations with friends, and a budget calculation later, I told P. that unfortunately she was beyond my budget, in particular since the cheapest haul out quotation at Papaya cove amounted to US$ 8,000. P. then dropped the price further, to around half of his original asking price. Revisiting the cost calculation, considering doing most of the work myself, I then thought it was manageable, and in combinations with registering her (she is currently not registered) I would actually add value to the boat and could always sell her again.

The next text to P. indicated that we would buy her. Money changed the owner in for different transactions and then she was ours.

Assessment

During the test sailing above the boat looked all right, it was a dry weekend and the interior had been cleaned up. The bilge had quite a bit of water though, but J., the caretaker said, that the hull does not have any leaks. I did check the hull with snorkel and mask, but without wearing scuba gear it is difficult, and my main worry with a 40 year old fiberglass boat (most likely made from polyester), OSMOSIS is my biggest worry. So the boat needs to get out of the water ASAP to do an assessment. That was clear. J. said that the main sheet traveler is leaking inside the hull, that is something that can be fixed.

My second visit happened during a rainy weekend (see section Puerto Galera Road Trip 1 below) was a bit shocking. J. did not have the time to prepare the boat before I came. It was humid inside and smelled badly of molds, rainwater was leaking through the screw holes of the starboard Genua traveler like little waterfalls, dripping on the electrical system, which was completely rotten. For a detailed assessment see Messing About in Boats page. So this will require a lot more work than I had planned for.

Still, no regrets yet, it is a 40 year old boat and it was reasonably priced, and it sails and motors well.

The Restauration

Stage 1: Initial work in Puerto Galera and Registration

The objective of Stage 1 is to restore the basic functionality, get the boat ready to test it to Pandan Island over Christmas / New Year and for moving it to the haul out location wherever that might be. For this the boat remains at the mooring in Puerto Galera, also because the Typhoon safety and the low cost of the anchorage there.

This is quite a challenge. First cost, the trip to Puerto Galera by car is quite expensive around US$ 250 for fuel, tollway fees and ferry, 10-20 US$ per night for accommodation, food of course and also paying guys from the club to help. It also basically takes two travel days in addition to the time working on the boat.

Second, another challenge is the availability of parts and the necessary tools. I am lucky that I am a hoarder of electric and electronic components. I have an electronics lab at home, and lots of stocks, it is more of a headache since it consumes quite a bit of space and lacking an office room in our small apartment… But lots of parts I have to buy locally or order and sourcing marine grade components is not easy. Amazon is out of the question since I am boycotting the billionaire owner. On Lazada it is possible, but difficult to identify genuine suppliers and good quality parts. Ordering from companies directly usually results in the parts ending up in customs storage with the need for customs clearance and even if DHK or an agent are doing it the cost is quite high, around 25% of the purchase value of the parts. With respect to tools I am probably as good equipped as a commercial workshop. But some I have to order, last week for example I tried to rebuild the manual bilge pump, had all parts but figured out that one M4 thread was gone. I have HELICOIL repair kits from my motorcycle projects for M5, M6, and M8, but not for M4. So I needed to identify a source (1 hour of internet search) and order. Still waiting for the tool and the pump repair is stalled in the meantime.

Third, a lot depends on the weather, after all it is Typhoon season, and on availability of the yacht club’s Service boat and J. and other guys for help. During the All Souls Regatta for example everybody was very busy.

Fourth: I have an excellent mechanical workshop at home plus the electronics lab. So as much as possible I want to do at home for efficiency and quality of work. But that requires shuttling broken parts to and repaired / rebuilt parts back from home.

So this really needs good PLANNING. For each visit I spend several hours in planning and coordinating. Making the parts also follows an overall schedule to make sure that I then can be as effective and efficient as possible on the boat. I try to follow the plan as good as possible, it is really useful to decide what to bring and take back every day given the limited amount of stuff I can cary. An example of such roadtrip plan is below.

October 15-19, 2025: Puerto Galera Roadtrip 1

- Assessed the electrical system and ended up ripping out all the components installed in addition to the original setup. Wrong components were used (e.g. house wires), components wrongly connected, etc. I decided to re-do the electrical system from scratch.

- Designed the new electrical system in KICAD.

- Took out the Switchboard and the distributor board with the terminals to make them at home.

- I had to leave PG a day early because another typhoon was approaching.

- Checked anchor winch cable and the remote control switch

In between

- Made control panel using plywood still available from Magayon II

- Made the switchboard panels from an old flexible solar panel.

- Bought new Santa Clara plywood, laminating epoxy and other supplies and started making the boards for the new cabin layout, Starboard side only.

- Identified and ordered lots of components for the electrical system

- Started re-building the manual bilge pump

- Designed and fabricated the new switchboard and the DIN rail board, ordered parts, work in progress.

- J. sealed the starboard traveller

- J. sealed the mast boot

October 28-November 2, 2025: Puerto Galera Roadtrip 2 and All Souls Regatta

This was a major work trip, sort of hindered by the Regatta.

- Cleaned out the electrical system further. Started to sort out the starboard battery compartment. Re-built fresh water pump is installed.

- Took out the false floor above the water tank starboard to take home and make a new one. Took out the frame of the control panel to take home.

- Changed dirk (but is too short). I have to be more careful and check what people say.

- Added 3 control lines and blocks for the spinnacker and genacker.

- J. H had fixed the starboard traveler, filled cracks with marine epoxy, sanded, primed, then painted. Re-attach the traveler rail with Sikaflex as seal. Looks good.

- Checked head, broke off wash basin hose (totally brittle) and bought a plug to temporarily fix it for the regatta. Ripped out all electrical cables of the toilet. We will install a manual toilet. During the sailing water entered at the seacocks. These need replacing.

- Did lots of small things.

- Prepared for the Regatta, 20l of diesel.

- Sailed 3 Regatta races

We had to leave a day early because of another Typhoon was approaching.

November 3, 2025: Marina Office in Batangas

On the way back from the All Souls Regatta, M. H accompanied me to the MARINA office in Batangas to inquire about the boat registration. We were told that:

- the application form I had used based on a download from the MARINA Manila office web page was the wrong one,

- they need a business registration from me as the owner (my consulting BIR certificate did the trick),

- the warf name in the Deed of Sale did not match the one in the Builder’s Certificate,

- we need the technical data of the boat on the page with the sketch, and

- I need to sign up to their database to be able to get a clearance for the proposed name of the boat. So back to the drawing table.

First thing is to have the Deed of Sale corrected. I corrected the Deed of Sale, and related documents, printed 4 copies, had M. and M. sign and sent everything to P. to check with the lawyers office in Puerto Galera whether it can be done at a cheaper cost than the 1% of the boat value.

Nov. 5, 2025 – Feedback from Polish Boat Registration

I had met B. during the All Souls Regatta, he is French, lives in Hong Kong, and has his foiling / racing trimaran registered in Poland. He gave me the contacts of the agent to did it for him. Seems to be very easy and straightforward. He showed me some of the email exchange he had with the company. I contacted them yesterday and they came back to me that I shall fill out the online form and that if the hull number can not be found (which is the case), the Polish Government would assign one to our boat.

Plan B in case the registration under Philippine flag is too complicated.

November 24, 2025: New Deed of Sale done

P. S sends me a text that we have a new Deed of Sale with the corrected boat name. I will pick it up at the end of the week on my next Puerto Galera Roadtrip. Time for fill out the new registration form and get all the required documents together.

In between road trips

- Finished new Control Panel including Switch Board, 220V controls, and wired it up as much as possible at home. Tested it.

- Continued re-building bilge pump.

- Ordered a lot of components.

- Fixed the Bimini top that provides shade in the cockpit (one day SAILRITE work)

- Finished the temporary instrument panel, starboard side. Will have to redesign that once we have speakers for the cockpit.

- Set up electro plating and electrolytically zinc plated the bus bars and the lift up handle

- J. sealed the port genua traveler

November 28- December 2, 2025: Puerto Galera Roadtrip 3

Day One: it’s just really frustrating. The boat is still not watertight. Water leaked somehow in the port side in the galley section, dripped on the blower I had stationed there to provide me with some cooling when working inside, and ruined it, it did not work anymore so I had to spend the whole day inside the cabin without any moving air. It was therefore a reasonably short day. Cleaned up the Control Panel area and sanded it. Then primed it with wood primer. The humidity inside the boat was so high that the water based acrylic paint just did not want to dry. Attached the DIN rail board to the hull. Looks good. Spent quite some time to rip out some of the modifications that one of the previous owners had done in the saloon, basically getting rid of the bunkbeds for whatever reason, and then took measurements for restoring the original configuration. I will make the parts at home and I hope that i can install them before the trip to Pandas Island on Christmas. In the afternoon Joel came, and painted the area of the Port traveler that he had fixed previously. Took the kitchen range from the boat to take home, it looks like it needs some attention. Barbecue night at the club in the evening, there were only six guests, including me. P. came later and we agreed to meet tomorrow morning at 9:30 to talk about about documents. In the evening in the Airbnb, I prepared cables for the control panel. Because I figured out that soldering on the boat is going to be really difficult, I would have to have the generator running nonstop. I also fixed the blower so that I can be more at ease tomorrow. Dropped my reading glasses and the frame broke at two locations and both lenses fell out. Unpacked the spare and that broke immediately too. Fixed the first one with heat gun glue so that I can work on the boat tomorrow (Sunday).

Day Two: I thought I was early, but when I left the Airbnb after breakfast, it was already 8:30. So I missed buying reading classes, getting gasoline, and I missed P. in the club. He had deposited the new deed of sale at the bar, so I at least got that in case I can not meet him anymore. Painted the Control Panel area white after the acrylic primer had thankfully hardened despite thi high relative humidity. Found a place for the main switch, drilled the holes and attached it. Arranged main fuse, Terminals for plus home battery, ground, ground before shunt and fuse box. Started wiring the thick cables for the battery connections. Had to identify what two so far unknown cables are for. Cleaned up the battery compartment and changed the strap for tying down the battery. Configured the strap with the EasyStich, in the process pierced another hole in my thump:-( I had to re-do all the large crimp eye connectors, they were all badly corroded. Tested the false floorboard that I made in SUBIC, it needs some minor modifications. Call to service boat at 5 PM because of a sort of worried that they stop and I couldn’t get back to the coast. A pizza and two San Miguel is in the roadside shop. Totally exhausted.

Day 3: Yesterday I figured out that I have actually booked the accommodation until Wednesday. Great, that gives me one more day, urgently needed because I am progressing slower than planned. Today was electrics day again. Finished the Starboard battery compartment with all the wiring of the main switch, main fuse, terminals, and started sorting out the wires according to where they lead to (bow, stern, control panel…). Started connecting the cables that still appeared good to the DIN rail terminals. However, I had to re-do all connections and shorten some cables until they were corrosion free. There are still three cables that I don’t know where they go to. Will see when I work in the cabins whether I can spot them there. The very original wires are I think beyond repair. Too corroded. Problem is that they are built into the fiberglass hull, so I cannot just replace them. Will have to put new cables parallel somehow.

Inbetween Road Trips

- .Mounted the Fuel and Water level gauges, connected and tested them. Made calibration curves for both using the tank sensors for connecting the sensors to Hal.

- Finished restoring the manual bilge pump after the Helicoil knock off from China arrived.

- Cleaned, de-rusted, primed and painted the reinforcement of the main winch starboard

- Made larger fiberglass reinforcement for smaller starboard winch

- Designed and made a frame for the alcohol cookstove of Magayon II. It will take more time to restore the LPG cloning system.

- Bought wood, screws and other parts for the restoration of the bunks.

- Cut out a total of 6 boards from plywood for restoring the bunks. Made the openings for storing stuff in the compartments (and accessing the electric components on the starboard side), made epoxy fillets for the screws, sealed all with epoxy

- Made a new 220V outlet panel with a cooling fan for the electric cabinet

- Made a new panel for the starboard side cockpit with space for a cockpit speaker

- Got a notice from MARINA office that all the documents I submitted for registration of the boat except for the copy of my IDs are not accepted. Bugger.

- Purchased remaining components for the electrical system

December 16 – 21: Roadtrip to Puerto Galera

Made good progress, but still slow.

- Installed white position light on the back. I had to re-do the cable totally, it was still the first one, interrupted at at least two locations and totally corroded. This involved climbing down into the aft hatch, removing old cables and fitting the new ones. The lamp delivered from China is very small, and does not look very durable. Cut a wooden base plate and painted it. I plan to replace it with a better quality lamp, “glued on” with silicone for the meantime.

- Repaired the bow navigation lamp (little 2 color lamp). Mounted it and put provisional cables (plan to replace it with two separate lamps later.

- Replaced and layer new wires for: Saloon lights, saloon port bench, kitchen power supply, head light, shower water pump, two spare lines for port bench in saloon (or head or front cabin), solar charger load, second plus (15b) line, front cabin light, ground cable to cockpit terminal, and many others . Restored legacy ground wire connections.

- Tested the anchor winch after restoring all connections and replacing the cables from the switchboard to the remote. (Clutch is broken, should have tested it before Joel mounted the winch). Took winch out again for repair of the clutch).

- Mounted SB floor board of bunk.

- Tested the level sensors for the fuel tanks. The sensor in Tank 1 is missing the magnet.

- Told J. NOT to remove the fuel sensors for checking the fuel and for refueling. Diesel spills make the cabin smell and every time a screw is removed and fitted again it wears a bit. Until it breaks. Very likely that the fuel sensor magnet was also lost this way.

- Refuelled diesel

- Discovered that the gasoline tanks are empty again. Total of 20 liters for a few hours of power tool use? There is some serious “leakage”. Unfortunately I will have to resort to the usual practice, only buy fuel when I need it.

- Note to self: When it rained a drip of water entered the switchboard area. It was running along the laminated channel for cables, probably coming from one of the leaning windows. I need to urgently fix the window seals.

- Got a bit frustrated again. I had bought brand new hinges for the anchor hatch. Polished stainless steel. After mounting, they are all covered in sealant or paint and look like 20 years old.

Stage 2: The Haul Out

Still to be arranged

Stage 3: Fine Tuning

This will stretch over more time since it is not so urgent. Includes the navigation instruments using OpenPlotter, making the cabins more livable, renovating the head etc.