Using what I learned at BOSCH in my studies at the University

Late 1980s, Stuttgart Hohenheim

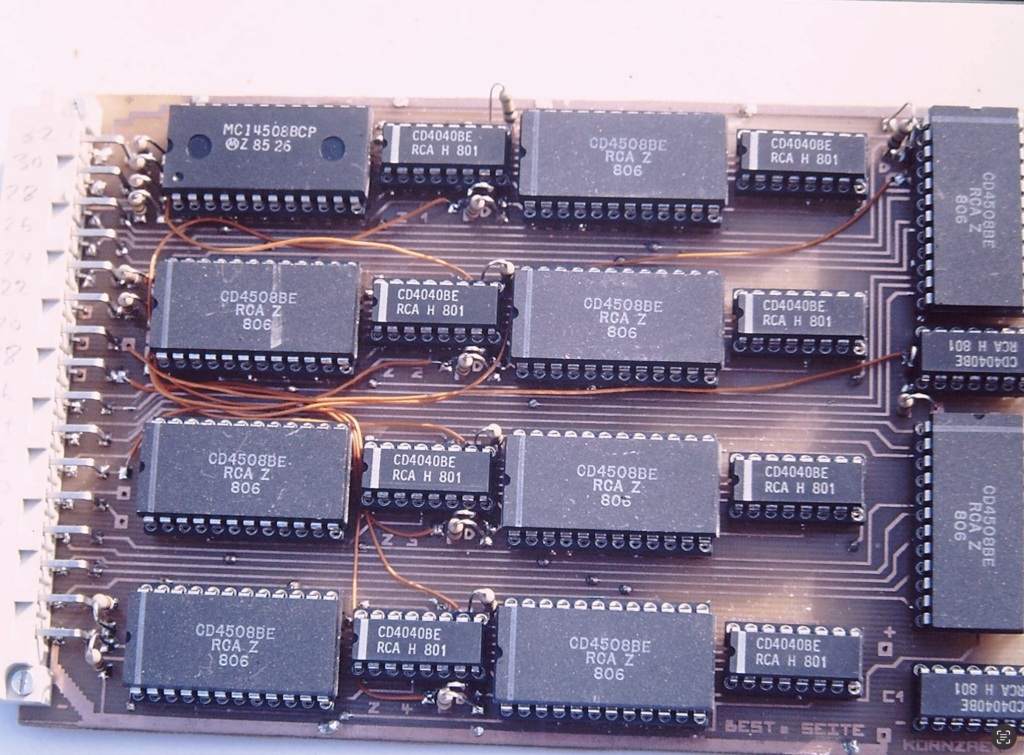

When cleaning up my FLICKR account I found these photos of my Studienarbeit, nowadays you would compare that with a BSC thesis. Under the guidance of a PhD student of Hohenheim University I developed the hardware for a system for measuring grain losses in a combine harvester. It consisted of 20 piezo crystals as sensors, 10 underneath the cleaner and 10 underneath the straw walkers. When a grain hit a piezo sensor a small voltage was generated. The electronics I designed and piloted had 20 channels consisting of amplifier and a digital counter, plus an interface to read out the data after a test run using a HP computer. Due to the vibrations of the combine the computer was shut down during the harvesting test run to avoid damage of the hard disk. After the test run the computer was turned on, the data read from the counters and then analyzed. It could then be determined where grain losses occurred under different combine operation conditions and throughputs and the machine could be optimized. After reading out the data the counters were re-set for the next test.

The PhD student went to work at a combine manufacturer after his studies. When I visited that manufacturer around 30 years later, the system had been commercialized. It was very gratifying to see that my studies as a student had contributed to a real-world application.